Total visibility, with item-level intelligence

Mojix is an end-to-end enterprise software innovator that delivers Real-Time, Item-Level Inventory Visibility at every intersection of your supply chain.

We help retail, luxury, food, and industrial manufacturing brands increase their profits and improve customer satisfaction by capturing and harmonizing better data with robust, fully integrated technology.

Turn your data into profitable decisions

Turn your data into profitable decisions

With the most advanced traceability features and headless API, Mojix is your all-in-one solution for total inventory maturity. Stitch together events across your enterprise leveraging any sort of serialized ID to bring all of your data together into a single, actionable dashboard. Leverage AI to suggest business optimizations.

End-to-End Visibility

End-to-End Visibility

Real-time inventory management

Production management and forecasting

FSMA 204 compliance

Digital product passports

Chain of custody records and traceability

Global KPI analytics

Standardized Data

Standardized Data

Centralized into one global cloud platform

EPCIS and GS1 compatible

GCP-hosted, multi-zone, and multi-regional with low latency that is SOC 2 Type II compliant

What happens when you have real-time item-level visibility in motion and at rest?

Complete supply chain solutions for global organizations

Complete supply chain solutions for global organizations

Headless API that’s scalable, smart, and secure

Headless API that’s scalable, smart, and secure

With Mojix’s headless API’s built on microservices architecture, you achieve full data harmonization. No matter your tech stack, we plug right in. We’re probably already integrated with your existing systems.

- Lot and Item Traceability

- Enterprise Systems Integration

- IoT Systems for Item-Level Tracking

- Secure, High-Performing Cloud Platform

Real-time item-level visibility

Real-time item-level visibility

Mojix Solutions

Mojix Solutions

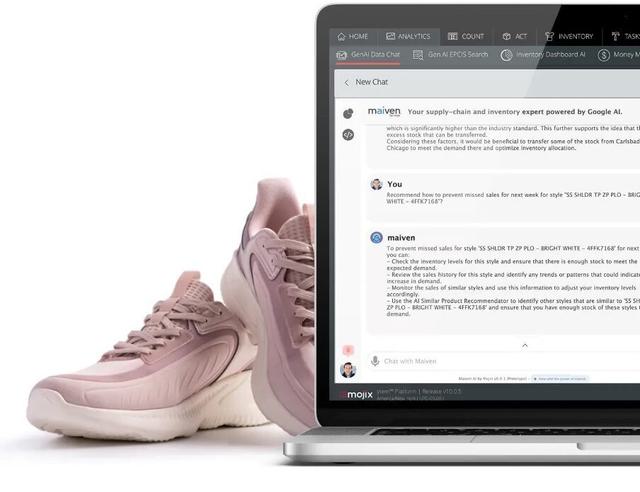

Industry: Any Supply Chain

Secure, harmonized data and generative AI to inform and accurately forecast your business operation

- Chat with natural language interfaces for instant inventory insights

- Receive actionable guidance on diagnosed issues in your inventory

- Empower merchandising and inventory managers with data-informed decisions

- Measure KPI impacts of inventory problems

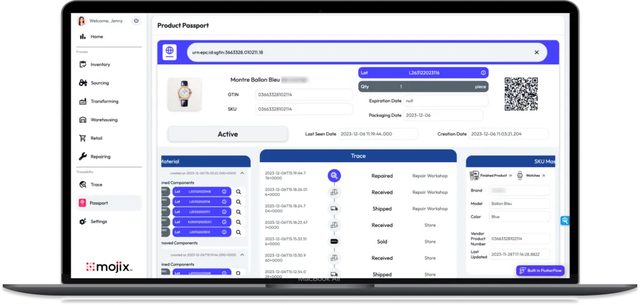

Industry: Food, Retail, and Pharmaceutical

Full traceability from source to shelf for advanced supply chain optimization

- Trace every item in your supply chain from origin to destination

- Stitch together events and data to provide a digital product passport

- Go beyond the SKU to know your inventory at an item-level

- Monitor your supplier and production quality

- Accurately respond to recalls and safety issues

- Maintain your brand’s transparency with consumers

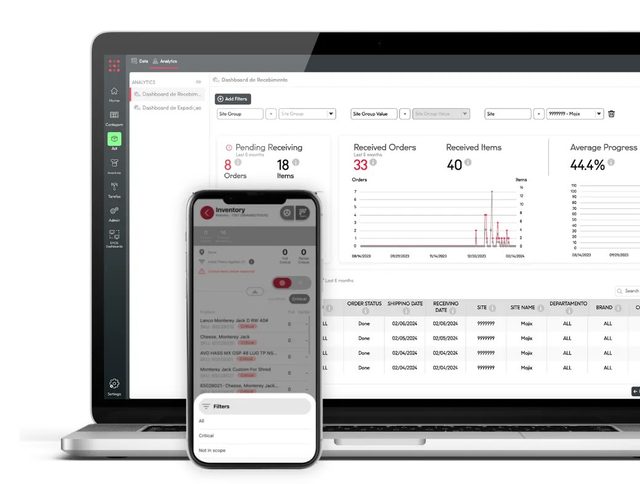

Industry: Luxury, Retail, and Food

Streamline your operation at every level and protect your brand

- Automate your processes

- Reduce labor costs

- Optimize labor efficiency

- Fulfill omni-channel orders

- Ensure food safety

- Achieve FSMA 204 compliance

- Reduce waste

- Stress-free RFID or QR code inventory tracking

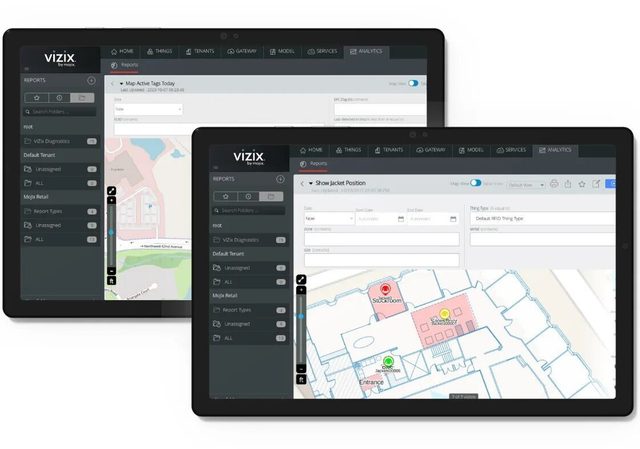

Industry: Industrial and Government

Simple, secure solutions for the most complex demands

- Automate your processes

- Reduce labor

- Obtain real-time, accurate data

- Establish RFID-equipped, item-level tracking

Streamline your process with one cloud-native platform

Streamline your process with one cloud-native platform

Mojix takes the confusion out of your supply chain and inventory infrastructure by combining everything—from software to IoT devices—into one user-friendly workflow.

Capture

Your data and its timelines

Apps | IoT | API | Enterprise Systems

Aggregate

Your operation data in real-time

Deliver

All data in a comprehensive, actionable workflow

WITH MOJIX

Bring all itemized data across enterprise systems into one traceability platform:

- Serialized Items

- Lots

- Batches

- SKU

- Containers

- Pallets

- Quantity

- Location

- Status

- Incidents

- Ownership

WITHOUT MOJIX

Track bits and pieces of information in multiple platforms and avenues:

Products: SKUs, Lots, Containers, Serialized

Shipments: Bill of Lading, ASN

Transactions: Invoices, Purchase Orders, Production Orders

Item-Level Traceability: The Key to Future-Proofing Food Brands

Learn more