IoT Asset Tracking

Vizix by Mojix

Total asset orchestration

Gain full visibility into your critical assets with Vizix™ — the IoT asset tracking platform built for operational efficiency. Vizix connects and tracks your assets across the entire supply chain, providing critical location data for items at rest. Know the real-time location and status of your inventory and equipment so you can reduce cost, optimize production, and ensure regulatory compliance.

Leading-edge asset tracking for connected brands

Leading-edge asset tracking for connected brands

Whether it’s heavy machinery or any other high-value asset, losing track of asset information leads to slowdowns and wasted productivity. With real-time item-level asset visibility, companies eliminate costly asset losses once and for all.

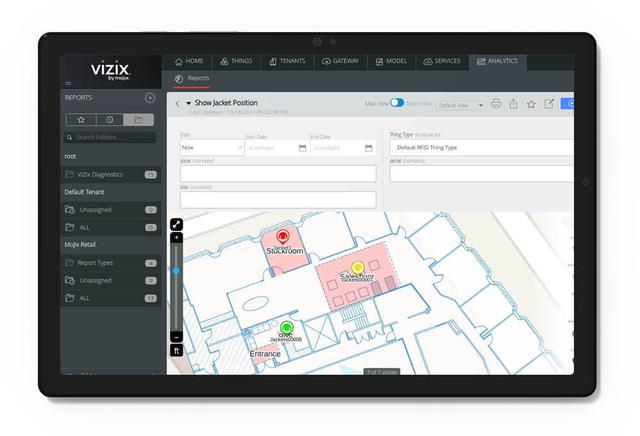

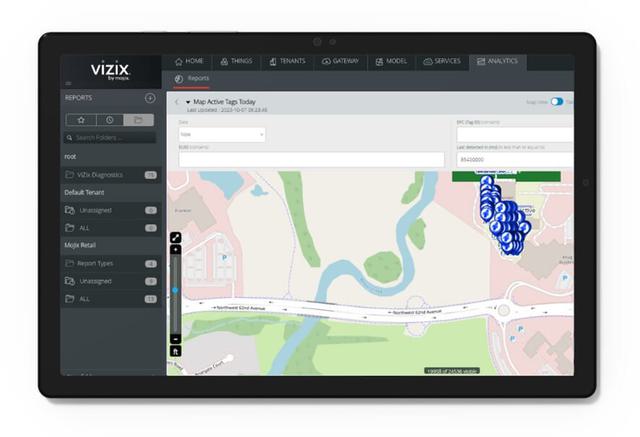

Vizix transforms real-time data from passive and active RFID, satellite, and other IoT sensors into interactive reports that inform your most crucial business decisions like ordering, replenishing, and shipping.

Track items with pinpoint precision

Track items with pinpoint precision

Vizix is more than just an asset tracking software. Gain intelligent operation insights that drive efficiency at every level of delivery:

- Autonomous asset discovery and association

- Zone-based, room-level, and sub-room location tracking

- Condition monitoring of temperature, moisture, shock, and more

- Historical audit trail for all asset movements and events

Real-time item-level asset management

Real-time item-level asset management

Wireless sensor networks

Item-level IoT data capture from Mojix leverages multiple hardware options for wireless sensors. With support for Bluetooth, RFID, WiFi, and other technologies, Vizix handles real-time data and works with your existing systems to ensure flexibility and global scalability.

- Automate workflows for smarter utilization and preventative maintenance

- Increase worker productivity by decreasing asset search time

- Data-proven asset lifecycle management from procurement to retirement

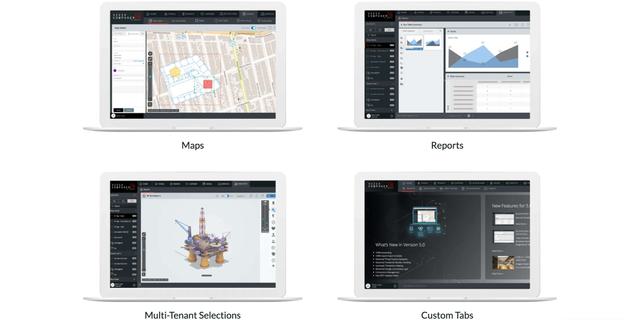

What's inside Vizix

What's inside Vizix

For all your IoT streams

For all your IoT streams

Vizix empowers businesses with the end-to-end data visibility they need to scale, streamline, and secure their bottom line. Harness its configurable application framework and elegant user interface to observe every movement of every asset — all in real time.

Vizix provides rapid time-to-value:

- Intuitive user experience requiring minimal training

- Scalable architecture for assets across multiple facilities

- Turnkey integration with ERP, WMS, MES, and other systems

- Cloud-based or on-premises deployment models

FedEx

Increase efficiency and minimize asset loss

Increase efficiency and minimize asset loss

Vizix for FedEx Fleet

Supply chain logistics giant FedEx uses Vizix asset tracking platform to reduce aircraft downtime and costs.

Total IoT asset intelligence at your fingertips

Companies can no longer afford to leave asset visibility to chance. Whether you need to track 100 assets or 100 million+, Vizix provides live monitoring, insights, and optimization capabilities to maximize ideal outcomes.

Item-Level Traceability: The Key to Future-Proofing Food Brands

Learn more